For anyone responsible for vehicle care, whether you’re a private car owner, part of a rental platform like Roadstr, or manage a fleet for special occasions, the integrity of your automobile’s filtration system is never just a technical footnote. The membrane filter cartridge quietly ensures clean fluids and air, safeguarding everything from powertrains to sophisticated onboard electronics. This guide highlights how membrane pleated filters contribute to trouble-free rides and smooth car rental operations, emphasizing their relevance for the automotive sector. When evaluating filtration solutions, understanding the landscape of leading membrane filter cartridge producers helps ensure you’re partnering with manufacturers who meet rigorous quality standards. Companies like Pullner Filter in Songjiang, Shanghai exemplify this commitment, operating 10,000 square meters of cleanroom facilities dedicated to precision filtration production.

Key Takeaways

- A membrane filter cartridge ensures ultra-clean fluids and air in automotive systems, critical for prolonged engine reliability and smooth fleet operation.

- Choosing the right membrane filter cartridge depends on application-specific factors like micron rating, material compatibility, flow rate, and connection type.

- Quality membrane filter cartridges, such as those made by Pullner Filter, meet rigorous international standards and support maintenance best practices for vehicles.

- Regular integrity testing, proper installation, and scheduled filter replacement maximize filtration effectiveness and vehicle uptime.

- Investing in high-quality membrane filter cartridges reduces maintenance costs, decreases downtime, and supports superior performance for both individual owners and rental fleets.

Understanding Membrane Filter Cartridges

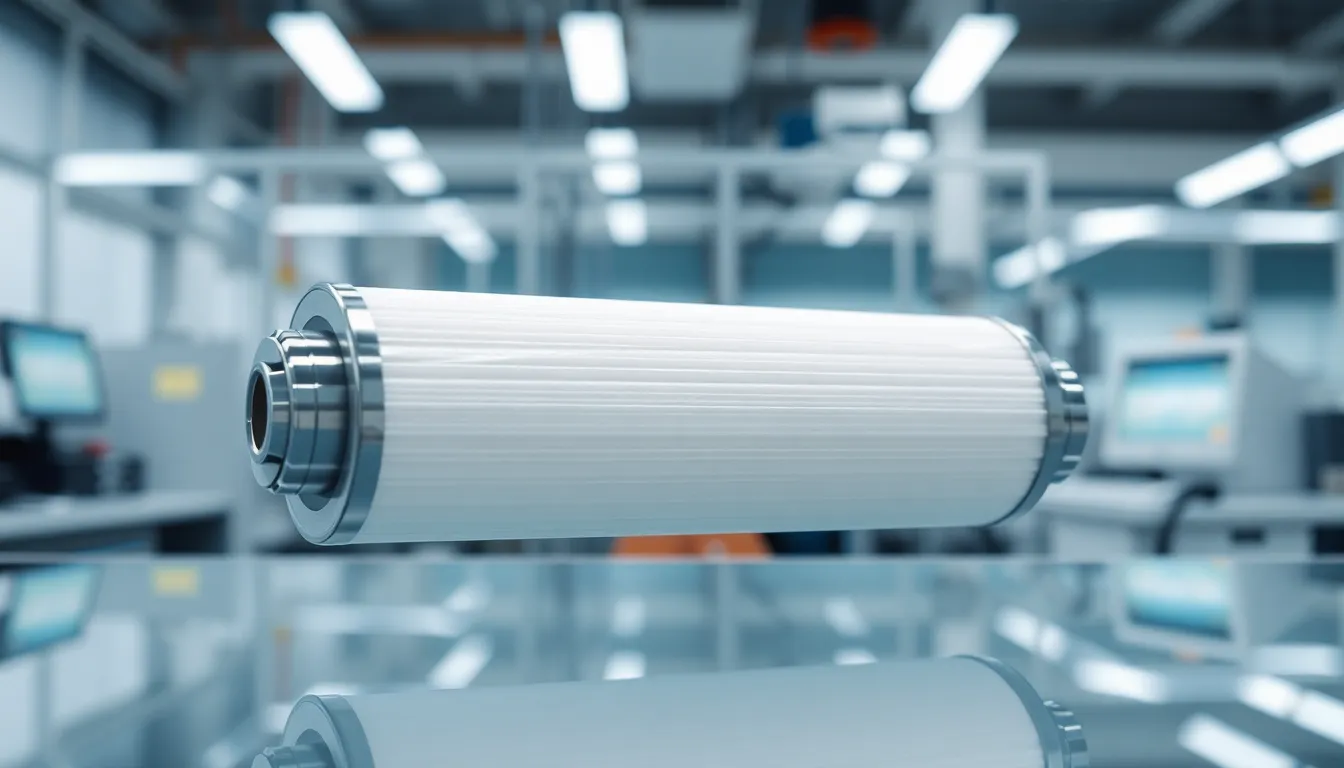

Membrane filter cartridges are precision-engineered devices that rely on ultra-fine porous membranes (PTFE, PES, nylon, or glass fiber) folded into pleats to create a vast surface area in a compact unit. Their main role is absolute filtration: physically removing tiny solid particles, colloids, microorganisms, and certain chemicals from liquids and gases, delivering efficiencies above 99.98% for particles as small as 0.05 microns.

Automotive applications demand filters robust enough for constant, high-throughput operations. Pullner Filter, for example, manufactures these cartridges under strict quality control in its 10,000 square meter cleanroom, using over twenty advanced production lines to ensure each filter meets rigorous international standards. The pleated structure not only increases contaminant-holding capacity but also maintains a high flow rate at low pressure drop, crucial for today’s high-performance vehicles.

Key Functions and Benefits in Automotive Applications

In the automotive world, membrane filter cartridges have moved from the periphery to center stage for clean fluids and air. Their functions span several mission-critical areas:

- Sterile Filtration: Ensures process water, used to wash parts and rinse paint, is free from bacteria and particulates, minimizing defects during vehicle production.

- High Dirt-Holding Capacity: Large pleated surface traps more debris, reducing changeout frequency and keeping long-term operational costs lower for rental fleets and private owners.

- Hydrophobic and Hydrophilic Properties: PTFE filters repel water, ideal for fuel systems and ventilation where water must be excluded. PES or nylon attract and filter waterborne contaminants, supporting ultra-pure water production for painting and electronics assembly.

Automotive manufacturing lines use these filters in every step, from powertrain assembly to paint shop final rinses. For rental operators or fleet managers, cleaner systems reduce downtime, prolonging intervals between maintenance and enhancing customer trust.

Types of Membrane Filter Cartridges Used in Cars

Different stages of automotive manufacture and operation require specialized filtration solutions. The most prevalent types include:

- PTFE (Polytetrafluoroethylene): Highly hydrophobic, making it essential for safeguarding fuel systems, vents, and components exposed to the elements. An example is the AVS series filter, which supports airflows between 3–150 L/h, suitable for protecting automotive batteries or air intake systems from water, dirt, and vapor.

- PES (Polyethersulfone): Hydrophilic by nature, PES filters deliver sterile filtration for water and gas lines. Common in final paint rinses and in parts washing systems that must meet stringent cleanliness standards.

- Nylon and Glass Fiber: Known for resilience against chemicals, these filters serve in paint, coolant, and sometimes oil filtration. Nylon captures particles down to 0.05 microns, making it a workhorse in high-contamination zones.

- Pleated Varieties (e.g., 3M Betafine XL): Designed to manage large flows with low resistance, perfect for automotive pre-RO (Reverse Osmosis) stages, paint lines, and process fluid recirculation.

Manufacturers like Pullner Filter tailor these cartridges in different lengths (5–40“), micron ratings, and connection types to seamlessly integrate with automotive processes.

Selection Criteria: Choosing the Right Filter for Your Vehicle

Picking the right membrane filter cartridge isn’t about grabbing the first one that fits. Key criteria include:

- Micron Rating: For automotive fluids and painting, choose filters rated at 0.05–0.2 microns to block fine particles and microbes.

- Material Compatibility: PTFE is best for acids, solvents, or fuel systems: PES works for water and sensitive chemical cleaning: nylon and glass fiber suit aggressive coolants and paints.

- Length and Flow Rate: Ensure the cartridge size matches your system’s flow requirements (from 5-inch lab systems up to 40-inch industrial setups).

- Certifications: For use in automotive parts fabrication touching food or pharmaceutical items (like interior filters), ensure they meet FDA, CE, or similar quality standards.

- Endcap and Connection Type: Verify fit with your system, options include DOE, SOE, and code 7 connections, as improper matches can cause leaks or bypass.

Pullner Filter supports clients through technical consultation, ensuring every filter meets both application and regulatory needs, minimizing risk during operation.

Maintenance and Replacement: Best Practices

Membrane filter cartridges last longer with the right handling. A few proven practices:

- Testing for Integrity: Use only integrity-tested, thermally bonded cartridges to avoid unnoticed failures or contamination events.

- Cleaning and Backwashing: Many PTFE and PES filters permit backwashing, periodically reverse flushing the filter extends life before replacement, especially in harsh environments like car painting or recirculated water systems.

- Scheduled Replacement: Monitor for pressure drops. A significant rise indicates clogging, risking fluid bypass. Swap filters at prescribed pressures (check manufacturer guidelines).

- Correct Handling: Always replace using gloved hands in a clean environment to avoid additional contamination.

Pullner Filter labels each cartridge with serial traceability and supplies clear maintenance protocols, helping fleet operators stick to schedules and keep their fleets in optimal condition.

Impact on Vehicle Performance and Longevity

Quality membrane filter cartridges protect sensitive car components, especially when vehicles see frequent use by different drivers, as with peer-to-peer rentals. Here’s the impact:

- Engine Reliability: Prevents injector and powertrain clogging by removing even the smallest particulates and water, ensuring smooth combustion and longer life.

- Ultrapure Water and Paint Processes: Eliminating surface residues and microbes reduces paint defects and corrosion, which matters for luxury, classic, and electric cars often rented for unique experiences.

- Less Downtime: Cleaner systems translate to fewer maintenance interruptions, keeping cars on the road and delivering on rental schedules.

- Lower Total Cost of Ownership: Fewer premature failures and less frequent part replacement means a better bottom line for both owners and rental platforms like Roadstr.

By investing in quality cartridges, especially those produced in ISO-certified factories like Pullner Filter’s 10,000 sqm cleanroom, companies and individuals build reliability and performance directly into their automotive assets.

About Pullner

Business: Pullner

Spokesperson: Lucy

Position: Sales Manager

Phone: 0086-21-57718597

Email: [email protected]

Location: LB19-Office No.1207, Jebel Ali Free Zone, Dubai, United Arab Emirates

Website: https://www.pullnerfilter.com/

Google Maps Link: https://maps.app.goo.gl/XgLZWHjGFcmdWddt6

Frequently Asked Questions About Membrane Filter Cartridges for Vehicles

What is a membrane filter cartridge and how does it work in cars?

A membrane filter cartridge is a device made from pleated membrane materials like PTFE, PES, nylon, or glass fiber. In vehicles, it filters out fine particles, microbes, and contaminants from fluids and air, protecting key systems such as the engine, paint lines, and electronic components.

Why is choosing the right membrane filter cartridge important for automotive applications?

Selecting the correct membrane filter cartridge ensures compatibility with the vehicle’s fluids and operating conditions. Proper filters guard against system clogs, extend the lifespan of components, minimize maintenance downtime, and help maintain optimal performance of rental fleets and private vehicles.

What are the main types of membrane filter cartridges used in vehicles?

The main types include PTFE, which is hydrophobic and ideal for fuel and air systems; PES, which is hydrophilic and used in water and gas lines; nylon and glass fiber for applications involving aggressive chemicals, coolants, or oil filtration, and pleated varieties for high-flow processes.

How often should membrane filter cartridges be replaced in automotive systems?

Replacement frequency depends on system usage and contamination levels. Monitor pressure drops as a sign of clogging and follow manufacturer guidelines for scheduled replacements. Regular testing and possible backwashing can prolong filter life in harsh environments like paint shops.

Can membrane filter cartridges improve vehicle performance and longevity?

Yes. By trapping particulates, water, and microbes, these filters prevent engine and component failures, reduce maintenance interruptions, and support higher reliability. This is especially beneficial for rental fleets and vehicles driven by multiple users.

What factors should I consider when selecting a membrane filter cartridge for my car?

Consider micron rating, material compatibility, cartridge size, flow rate, certifications (like FDA or CE), and connection type. Ensuring each filter matches your vehicle’s requirements helps prevent leaks, contamination, and ensures regulatory compliance.